Vertical announces the opening of the Vertical Energy Centre, the UK’s most advanced aerospace battery facility

Global aerospace and technology company that is pioneering zero-emissions aviation, Vertical Aerospace, has announced another significant UK investment and innovation milestone with the opening of the Vertical Energy Centre (VEC), believed to be the UK’s most advanced aerospace battery facility, based in Bristol.

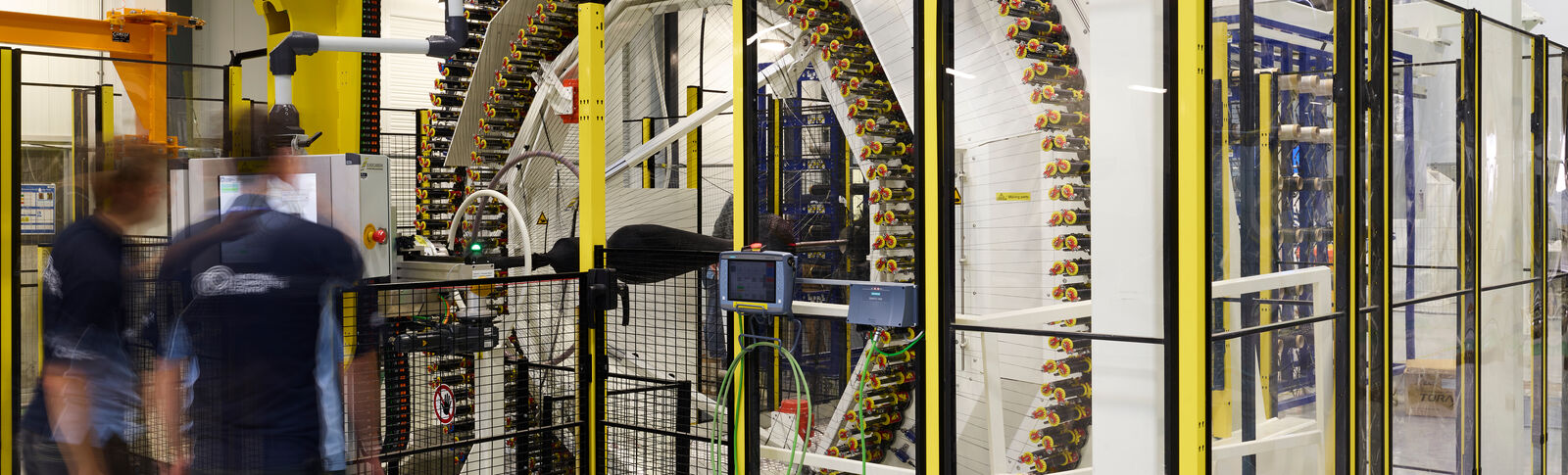

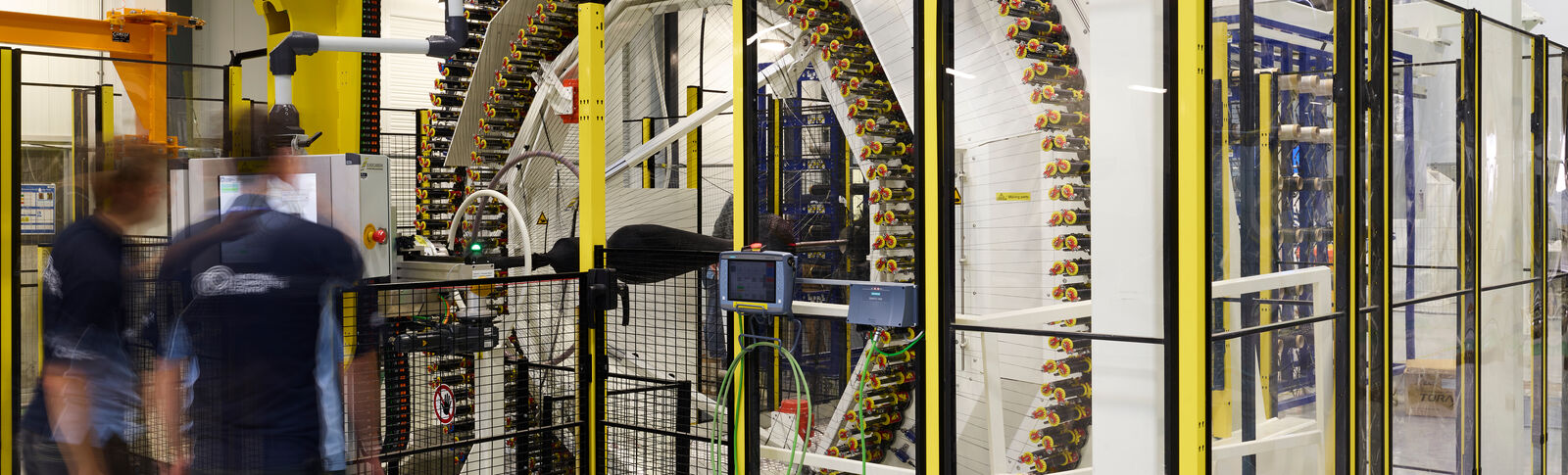

The multi-million-pound state-of-the-art, 15,000ft2 facility, is one of the only dedicated aerospace battery facilities in the UK. It is home to Vertical’s current 50-strong battery team – drawn from the likes of McLaren, the European Space Agency, Jaguar Land Rover, Airbus, Rolls-Royce and Dyson – who are developing proprietary battery technology that is enabling greater power to weight ratios for eVTOL flight. These frontier technologies are expected to transform what has been possible with battery technology to date.

Vertical announced last year its strategic partnership with Molicel, which combines Vertical’s proprietary battery pack design with Molicel’s leading cell technology. Vertical has already conducted significant cell testing at the VEC for use in our battery pack modules. Operational ramp-up of Vertical’s battery

manufacturing machinery has begun by assembling the first in-house developed prototype battery modules in the facility.

Vertical’s battery systems have undergone a wide range of testing, including temperature, conducted emissions, vibration, thermal durability and characterisation, propagation and drop testing at the VEC. Vertical has previously had significant progress with battery tests, having carried out crash and thermal runaway testing under European Union Aviation Safety Agency and the UK’s Civil Aviation Authority supervision.

Vertical has developed significant intellectual property around battery design including cell packaging, cooling and electronic battery management systems to deliver high-power, high-performance battery packs capable of powering eVTOL aircraft. Vertical is aiming for entry into service with a 220Wh/kg battery system. This will enable Vertical’s VX4 to conduct back-to-back missions, with fast-charging cycles in-between, and minimised impact on the packs’ cycle life.

This announcement follows the recent news that Vertical secured £14m in funding from the Aerospace Technology Institute (ATI) through a joint initiative with the UK government, to further progress the development of its battery technology.

Dr Limhi Somerville, Head of Vertical’s powertrain team said, “Aircraft require high-performing and safer batteries than anything on the market today. This facility and our core technology will unlock this, bringing the reality of electric flight even closer.”

Stephen Fitzpatrick, Founder and CEO of Vertical, commented, “Delivering the electric aircraft of the future requires innovation at its best which is why we are championing UK electric battery development. Our world-class team in Bristol will be pushing new boundaries to design battery systems fit for electrifying our future.”

UK Minister for Investment, Lord Johnson said: “Vertical’s investment in cutting-edge battery technology brings us one step closer to delivering zero-emission flight, a central objective of the Jet Zero Council. Tomorrow’s technologies like zero-emissions aviation will not only provide a boost to sustainable growth, but are essential for generating the new, high-quality jobs that will take Britain’s economy into the future.”

Related Articles

Count Published date4 July 2022

Published date4 July 2022  Published date10 November 2022

Published date10 November 2022  Published date19 March 2025

Published date19 March 2025

Published date14 July 2022

Published date14 July 2022  Published date4 July 2022

Published date4 July 2022

Published date14 September 2023

Published date14 September 2023

Published date14 July 2022

Published date14 July 2022

Published date16 June 2022

Published date16 June 2022

Published date8 November 2022

Published date8 November 2022