Digital & Tech case study: Q5D

Q5D's innovations drive Industry 4.0, electrification, net-zero, and sustainable growth

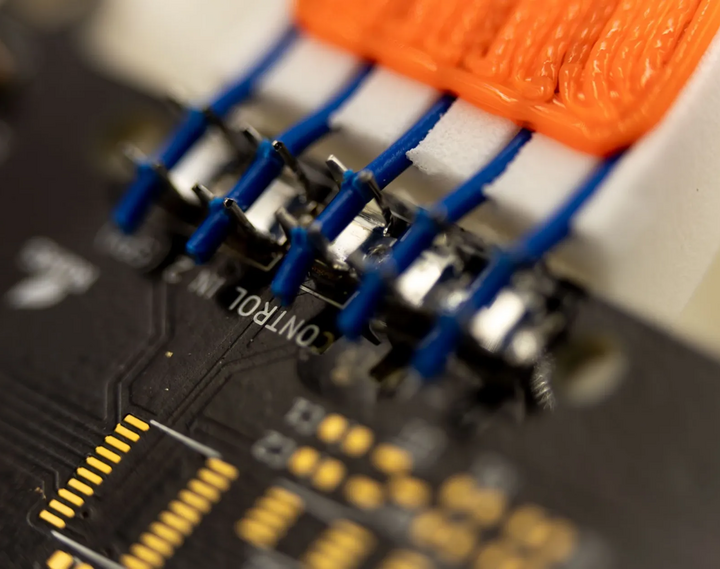

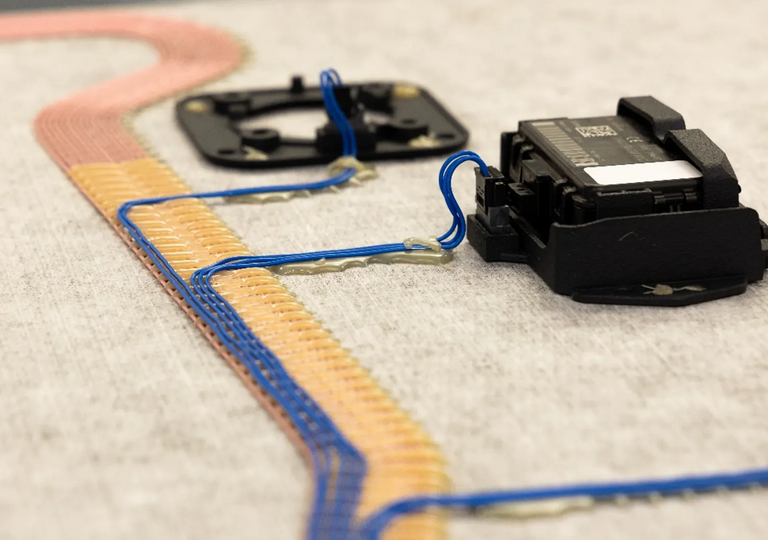

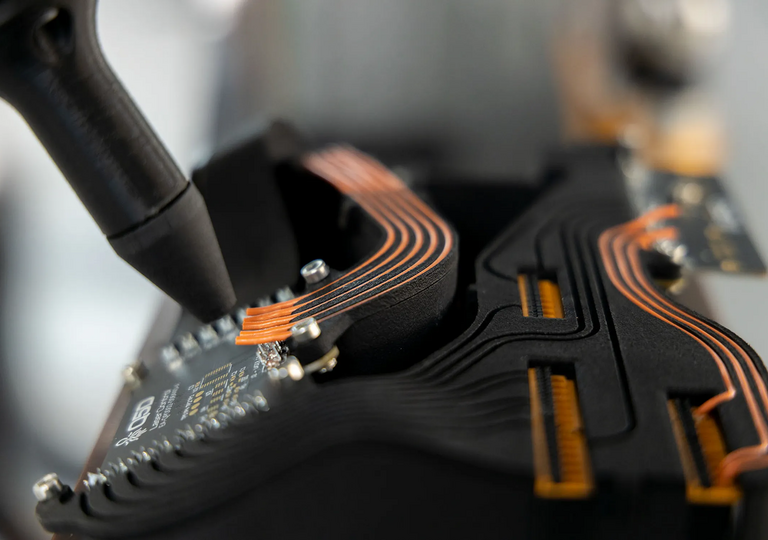

Automated wire harnesses, assemblies of electrical cables or wires that transmit signals or electrical power, are being revolutionised by Q5D in North Somerset. By automating the entire routing of wires, rather than just assisting manual processes, or automating discrete tasks like cutting and stripping wire, Q5D is leading the way in robotic and manufacturing automation for these harnesses. This comprehensive automation enables the entire wire harness assembly process to be completed robotically, offering unprecedented efficiency and precision.

Automated wire harnesses, assemblies of electrical cables or wires that transmit signals or electrical power, are being revolutionised by Q5D in North Somerset. By automating the entire routing of wires, rather than just assisting manual processes, or automating discrete tasks like cutting and stripping wire, Q5D is leading the way in robotic and manufacturing automation for these harnesses. This comprehensive automation enables the entire wire harness assembly process to be completed robotically, offering unprecedented efficiency and precision.

They aim to make electrical functionality as integral to products as their mechanical and physical form. By pioneering new material application techniques and advancing robotics and CAM software for multi-axis additive manufacturing, they enable full automation of production processes.

"We chose to locate in the West England because of the availability of a highly skilled and entrepreneurial workforce. Being able to find great people is critical to our future. The Bristol and Bath area has many hi-tech companies and leading universities, and that made it a great choice for Q5D."

Image credit: Q5D

Image credit: Q5D  Image credit: Q5D

Image credit: Q5D Key achievements

Product launch and development

In June 2023, Q5D proudly launched its first product, the CY1000 machine, revolutionising the process of making wire harnesses. This machine has been instrumental in demonstrating and refining new manufacturing processes, setting a new standard in the industry.

Industry engagement and collaborations

Since the launch, Q5D has attracted significant interest from multiple automotive Original Equipment Manufacturers (OEMs) and Tier 1 suppliers. The company has also continued its collaboration with customers in the Aerospace and Defence sectors, broadening its impact across various high-tech industries.

Technological advancements

In the past few months, Q5D has made remarkable strides in technology and process development, including:

- Developing new processes and equipment for depositing glue to secure wires to various surfaces.

- Increasing the speed of operation for greater efficiency.

- Enhancing software tools to provide a fully digital manufacturing option.

- Working on diverse projects ranging from motor racing to satellite manufacturing.

Investment and growth

Q5D recently secured a significant investment led by Lockheed Martin, amounting to $3 million USD. This investment is a testament to the company's innovative approach and potential to transform the wire harness manufacturing industry.

Image credit: Q5D

Image credit: Q5D Future plans

Production expansion

In 2024, Q5D plans to construct its first production-ready large format machine, the SQ25. This new machine will be more than twice the size of the CY1000 and will enable the processing of large automotive and aerospace components up to 1.5m x 2.5m.

Pilot projects

A number of SQ25 machines are being prepared for various pilot projects around the world, showcasing Q5D's commitment to global innovation and industry leadership.

Job growth projections

Q5D anticipates significant job growth over the next three years:

- 2025: 20 new jobs

- 2026: 30 new jobs

- 2027: 40 new jobs

Support in the region

Q5D has received invaluable support from the Invest Bristol & Bath team, who facilitated introductions to the West of England Growth Hub and secured assistance from IUK Business Growth via Business West. These approachable support teams provided a wide network of contacts and information, significantly aiding Q5D's setup and expansion efforts.